- +91-9811787643

Enquiry.gmw@gmail.com

Milling Section

Efficient Air Classifier Grinder for Precision Milling

Air Classifier Grinder is an ultra-efficient milling machine capable of precision and fine grinding of powders. It integrates grinding and classification into one system, which guarantees the homogeneity of the particle size and output of high quality. Such equipment is also common in food, chemical, and pharmaceutical industries, where the most important factors are precision and consistency.

In its high technology, the grinder generates less heat during the process, thus it can be used on heat-sensitive materials. It is easy to operate, maintains low maintenance and is compact in size, which conserves space. The classifier automatically isolates minute particles and coarse particles and gives a smooth and efficient working performance.

The Air Classifier Grinder is designed using durable materials, therefore guaranteeing extended durability and consistent performance during continuous production. This machine improves productivity and quality, whether it is spices, grains or industrial powders. The Air Classifier Grinder is a reliable alternative to those companies that want a consistent and fine grinding.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Automatic |

| Application | Industrial |

| Principle | High Air Throughput In The Grinding Area |

| Air Conversion | High Amount Of Air Converted Into Turbulence |

| Guidance | Appropriate Guidance Of The Air Stream In The Mill |

The Distinctive Principle Of Air Classifier Grinder Is Based On A High Air Throughput In The Grinding Area. This High Amount Of Air Is Converted In To A Tremendous Turbulence By The Rotating & Stationary Parts Of The Machine As Well As By An Appropriate Guidance Of The Air Stream In The Mill. This Machine Is Best Suitable In Pharmacutical Industry.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Grinding Equipment |

| Material | Various Materials Including Thermoplastics, Rubbers, Elastomers |

| Application | Empower Cryogenic Grinding By Cooling Materials To Embrittlement Temperatures |

| Packaging Type | Multicolor |

| Cooling System | Fluid Nitrogen Cooling System |

| Particle Size | Can Quickly Reduce Materials To The Specified Size For Industrial Grinding Applications |

| Specialty | Suitable For Materials Unacceptable For Crushing At Surrounding Temperatures |

| Expertise | Comprehensive Knowledge Base In Cryogenic Grinding Technology |

Cryogenic grindingmill feeders are designed to empower cryogenic grinding by cooling materials to embrittlement temperatures using fluid nitrogen. Cryogenic grinding innovation guarantees that materials that don't pound at encompassing temperatures will accomplish a cool sufficient temperature for fine crushing when they reach the pulveriser or pound process.

With cryogenic grinding hardware from Gobind Machinery Works, you can quickly diminish materials to the specified size for your most requested mechanical grinding applications. Our cryogenic grinder manufacturer in Delhi uses a fluid nitrogen cooling system to empower exact molecule measurement dispersion for thermoplastics, rubbers, elastomers, and other materials unacceptable for crushing at surrounding temperatures.

As a driving company in cryogenic grinding innovation, we have the comprehensive information base required to direct our clients on the right course and offer assistance in securing the cryogenic grinding gear best suited to their needs.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Milling Machine |

| Material | Hardened Steel |

| Packaging Type | Gray, White |

| Usage | Size Reduction By Impact |

| Number Of Hammers | Four Or More |

| Shaft Type | Central |

| Speed | High Speed |

| Chamber | Enclosed Within A Rigid Metal Case |

Hammer Mills Consist Of A Series Of Hammers (Usually Four Or More) Hinged On A Central Shaft And Enclosed Within A Rigid Metal Case. It Produces Size Reduction By Impact. The Materials To Be Milled Are Struck By These Rectangular Pieces Of Hardened Steel (Ganged Hammer) Which Rotates At High Speed Inside The Chamber.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Grinding Machine |

| Material | Metal |

| Packaging Type | Industrial Standard Packaging |

| Usage | Grinding And Pulverizing Materials Into Powder Form |

| Principle | Impacts And Shearing |

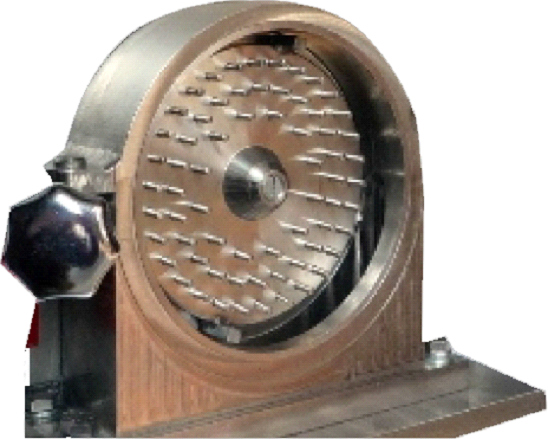

Pin Mill Work By Similar Principle As Hammer Mills (Impacts And Shearing) But With Typically Faster Tip Speed Rotor Configuration Of Intermeshing Pins Which Impact The Particles As Solids AND MAYERIAL IS TRANSORMED INTO POWDER FORM AND Cooling Of The Rotating Disks Is A Useful Way Of Removing Heat From The Mill.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Grinder |

| Feature | PLC Controlled,Self Cleaning Machinery,Temperature Set Grinding,Rpm Control Grinding,Dry Chilled Grinding,Speed Control,Temperature Control,Aroma And Color Preservation,Admin Access,Auto Fault Detection,Automatic Cut-Off On High Motor Temperature,Dry Chil |

| Packaging Type | White |

| Application | Electric Industry |

Self Cleaning Machinery, Temperature Set Grinding, Rpm Control Grinding, Dry Chilled Grinding

Latest Pattern Of Grinding Ever Introduced In Indian History. It Works On The Following Points -

- Speed Can Be Controlled Of Grinding

- Temperature Can Be Control Of Grinding

- Aroma And Color Can Be Save While Grinding

- Different Speed For Different Products

- Admin Access Grinding

- Auto Showing Fault

- Automatic Cut-Off On High Temperature Of Motor Etc.

- Dry Chilled Air Grinding

All These Points Without Disturbing Your Production And Enhancing Your Quality.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Driven Type | Electric |

| Packaging Type | Blue |

| Automatic Grade | Automatic |

| Number Of Flower | Machine |

| Application | Crushing Solid Material Into Fine Particles |

| Method | Crushing, Impacting, Grinding |

| AdditionalInfo | Machine Added By Thermal Expansion For Pulverizing Blocks And Items |

The Pulverizer Is A Machine Added By Thermal Expansion. It Smashes Blocks And Items And Pulverizes. It Is The Process Of Crushing Solid Material Into A Fine Particles Of Less Than 5 Mm. Pulverization Method Includes; Crushing, Impacting And Grinding. A Pulverizer Or Grinder Is A Mechanical Device For The Grinding Of Many Different Types Of Materials.