- +91-9811787643

Enquiry.gmw@gmail.com

Material Handling System

Leading Manufacturers, Exporters, Wholesaler, Retailer of Magnets & Magnet Products, Roasters, Bag Dump Hopper, Bag Filling and Stitching System, Batch System, Belt Conveyor, Bin Activators, Bucket Elevator, High Pressure Fan, Load Cell, Plant Shifter, Pneumatic Diverter, Pressure Conveying System, Rotary Airlock and Screw Conveyor from Delhi.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Packaging Type | Gray |

| Application | Industrial Applications |

| Innovation | Key Focus |

| Research Unit | Well-defined |

| Client Satisfaction | High Priority |

| Industry Standards | Followed |

| Workers | Proficient |

At Gobind Machinery Works, we area manufacturer of Hopper Magnets catering to clients worldwide. Over the years, we have effectively overcome the industry's leaps and bounds and grasped victory. Innovation is an added substance of our item, and to achieve this, we conduct broad researchin our development unit.

These tests and overviews assist us in meeting our client's needs and support us in planning and creating fabulous items. A group of proficient workers well versed in all the manufacturing forms and other related errands have made a difference in extending our business to include all of them. These faculty members are entirely committed to trade morals and have backed us up with the most extreme true endeavours.

Further, we aim to achieve the highest client satisfaction and achieve the assignment. We devote our true endeavours to enhancing items in our well-defined research and improvement unit.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Rotary Dryer |

| Material | Metal |

| Usage/Application | Drying Material In A Rotating Drum With Drying Air |

| Heating Method | Indirect Heating |

| Drum Position | Slight Horizontal Slope |

| Packaging Type | Gray |

ROTARY DRYER Rotary Dryers Work By Tumbling Material In A Rotating Drum In The Presence Of A Drying Air. They Can Also Be Indirectly Heated To Avoid Direct Contact Between The Material And Processing Medium. The Drum Is Positioned At A Slight Horizontal Slope To Allow Gravity To Assist In Moving Material Through The Drum.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Bag Dump Hopper |

| Material | Steel |

| Packaging Type | Silver |

| Application | Feeding Machinery At A Distance, Dust Removal |

| AdditionalInfo | Pre-installed With Magnets And Dust Control Unit |

Product Details :

- Feeding Any Machinery Installed At A Certain Distance Through Means Of Elevator, Pneumatic Suction Or Pusher System.

- Pre-Installed With Magnets And Dust Control Unit For Removing Dust From The Line.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Applications | Automatic Weighing Of The Bags, Automatic Stitching Of The Bags |

| Bag Weight Capacity | 10kg To 25kg |

| Stitching Type | Automatic |

| Packaging Type | Gray |

| Packaging | Industrial Standard Packaging |

Applications :

- Automatic Weighing Of The Bags

- Automatic Stichng Of The Bags + Your Brand Name

- Stichting Of Bags Weighing 10kg To 25 Kg

- Complete Online Stitching Of Bags

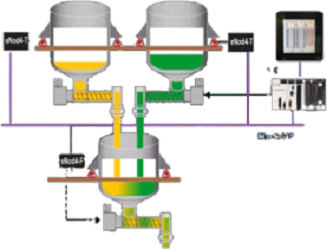

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Batch System |

| Application | Industrial |

| Control System | Scada Software |

| Remote Control | Control The Complete Plant From Your Phone |

| Packaging Type | Multicolor |

Product Details :

- This System Is Specially Designed For Mixing Several Ingredients For Making One Product.

- This System Works On Scada Software

- You Can Hide Your Ingredients Formula From Other’s

- You Can Control The Complete Plant From Your Phone

- Online Measuring Of Different Products And Their Blending + Grinding – Complete Online Unit.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Belt Conveyor |

| Usage | Material Lifting, Feeding Machines, Shifting Material, Loading Trucks |

| Packaging Type | Multicolor |

| Customization Options | Different Lengths, Sizes Available |

| Material | Steel |

Product Details :

- This System Is Used For Lifting Material From The Bottom And Feeding Any Machine Or Shifting Material To Another Floor Or Loading Trucks.

- It’s Speed Can Be Controlled According To The Product.

- Different Length And Size Can Be Create As Per Customer Need.

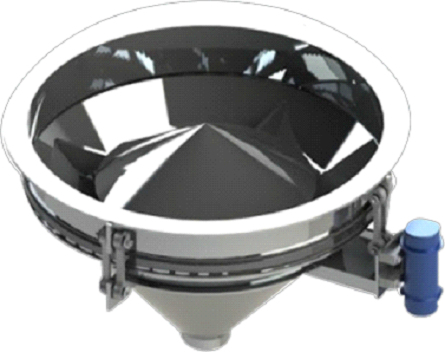

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Bin Activator |

| Material | Steel |

| Packaging Type | Silver |

| Usage | Moving Sticky Materials From Silos |

| Power Consumption | Low |

Product Details :

- This System Is Used Under The Silo’s For Moving The Stichy Matrial From The Silo’s Without Changing The Form Of Product.

- Power Consumption Is = To No.

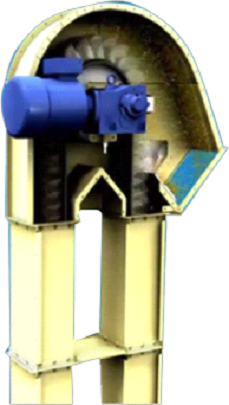

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Industrial Equipment |

| Material | Steel |

| Packaging Type | Silver |

| Packaging | Industrial Standard Packaging |

| Application | Industrial |

A Bucket Elevator Can Elevate A Variety Of Bulk Materials From Light To Heavy And From Fine To Large Lumps.The Bucket Elevator Is The Enabling Technology That Permitted The Construction Of Grain Elevators. A Diverter At The Top Of The Elevator Allows The Grain To Be Sent To The Chosen Bin.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Packaging Type | White and Black |

| Power Source | Electric |

| Pressure | High Pressure |

| Automation Grade | Semi Automatic |

| Application | Pneumatic Suction, Pneumatic Grinding, Material Lifting |

| Number Of Flower | Fan |

| Material | Metal |

It Is Use For Several Phases:

- As In For Pneumatic Suction Of The Material

- As In For Pneumatic Grinding

- As In For Lifting Material Upto Any Height

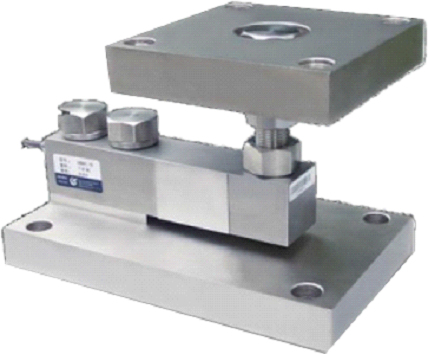

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Load Cell |

| Application | Checking Weight Of Mixture, Blender, Silos |

| Packaging Type | Gray |

| Quantity | Bigger Lot While Mixing Different Products |

| Industry Standards | Typical Values Inferred |

Product Details:

- This Setup Is Used ForChecking The Weight Of Your Mixture / Blender / Silos At Any Place.

- Making A Bigger Lot While Mixing Different Products With Lesser Quantity.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Plansifter |

| Material | Various Materials For Different Sections |

| Application | Sifting Granular Materials In Flour Mills |

| Power Source | Motor-driven |

| Sections | 4, 6, Or 8 Sections |

| Installation | Motor Installed Inside The Main Frame |

| Special Feature | Counter-balanced By A Counterweight |

Plansifter Is Driven By A Motor Which Is Installed Inside The Main Frame And Counter-Balanced By A Counterweight. Each Machine Has 4, 6, Or 8 Sections Sieves Inside. Different Materials Flow Into Different Sections On Their Own Route. According To Individual Design For Different Materials, The Sieves Sift Different Granular Materials To Different Passages In Flour Mills When The Whole Machine Is Running.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Diverter Valve |

| Material | Metal |

| Packaging Type | Silver |

| Application | Connecting Two Different Output Lines At One Feeding Point Pneumatically |

| Efficiency | 100% |

It Is Use For Connecting Two Different Output Lines At One Feeding Point. It Is Connected Pneumatically & 100% Efficency Is Achieved.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Packaging Type | Grey |

| Automatic Grade | Automatic |

| Application | Industrial |

| Number Of Flower | Pressure Conveying System |

| Power Consumption | Low Power Consumption |

| Industry Standards | Efficient Material Conveying System |

Product Details :

- This System Conveys Your Material With A Push Blow System Which Consumes Less Power Consumption.

- We Can Fill As Much Silo’s We Want To Fill.

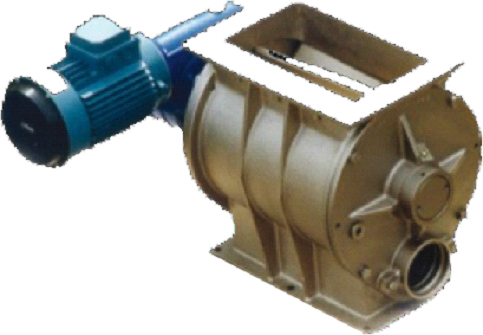

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Rotary Valve |

| Material | Stainless Steel |

| Packaging Type | Silver, Blue |

| Application | Industrial |

From The Air Lock Inlet The Air-Product Mixture Enters The Chambers, Which Are Created By Fixing Blades (Wings) On The Rotor Shaft. Due To The Precise And Standard Tolerance Between The Body Housing And The Rotor, The Product Is Separated From Air And Discharged Regularly Without Any Leakage.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Number Of Flower | Auger Conveyor |

| Material | Metal |

| Packaging Type | Metallic |

| Application | Moving Granular Materials |

| Industry | Bulk Handling |

A Screw Conveyor Or Auger Conveyor Is A Mechanism That Uses A Rotating Screw Blade Within A Tube, For Moving Granular Materials. They Are Used In Many Bulk Handling Industries. The Rate Of Volume Transfer Is Proportional To The Rotation Rate Of The Shaft.