- +91-9811787643

Enquiry.gmw@gmail.com

Forte-In

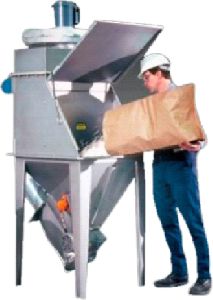

The entire range of products manufactured by us is fabricated using high grade material and latest technology. We are backed by a team of professionals who makes sure that t5he entire range is manufactured in accordance with the national and international norms and standards. Furthermore, we have always satisfied our clients with timely delivery of all the products.

At Gobind Machinery Works, our company is recognised as a driving double-cone blender manufacturer in Delhi. With many years of gear manufacturing experience, we offer a broad production line of quality machines, counting bottle washing machines, tablet press machines, fluid filling machines, liquid bed dryers, and revolving bottle washing machines. Committed to strict quality control and mindful client service, our experienced staff is continuously accessible to examine your needs and guarantee total client satisfaction.

Through serving different companies in entirely different nations, we accept that victory will be influenced by victory. Our company mission is to make a proficient stage for the industry and accomplish individual value. Whether choosing an existing product from our catalogue or accepting building back for your application, you can talk to our client service centre about your sourcing necessities.

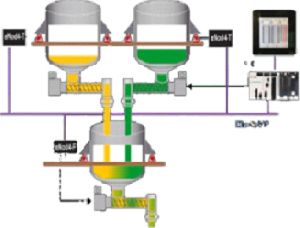

We offer total production solutions from raw material processing to finished items. We manufacture and supply different equipment and pressing tools with our design and after-sales service groups.

Other Forte-In